We’re not trying to confuse you. I promise.

In our continuing effort to explain letterpress printing, we eventually need to approach blind printing. The purpose of this post is to help clarify the terminology, because it gets confusing really quickly. We’ve covered this topic a little in the past here. But before we update that post, we wanted to chat about blind in general.

So what is blind?

Blind printing is when there is no ink used for that portion of the process. This is a really cool design element uniquely available to letterpress printing. Letterpress printing utilizes a physical plate or die that is pressed into the paper to create an impression, this impression is legible even in the absence of ink. You can’t achieve this effect with any other common printing methods.

So what’s the difference?

Okay. Let’s get down to the brass tacks. The reason we want to make the distinction between these two terms is because they are often used interchangeably. But they are not the same thing on press, and require different dies/plates, and also have different costs associated with them.

When we refer to a deboss, it is in direct relation to an emboss. A rigid die is created that sandwiches the paper between two pieces of a die to simultaneously create the emboss/deboss effect on your project. So you can’t have a deboss without an emboss on the opposite side (because they happen at the same time and are a result of the same action). Sometimes people refer to a traditional letterpress impression as a deboss, which gets confusing because there is no resulting emboss. Both emboss/deboss and traditional letterpress can be done blind.

If you are interested in learning more letterpress terminology, check out last weeks blog post here.

Please see the pictures below that help demonstrate the difference:

Blind letterpress impression and white foil for Medical Professionals Board.

Business card for Goodwin Media with blind flood.

Letterpress business cards for Faktory incorporating blind design elements.

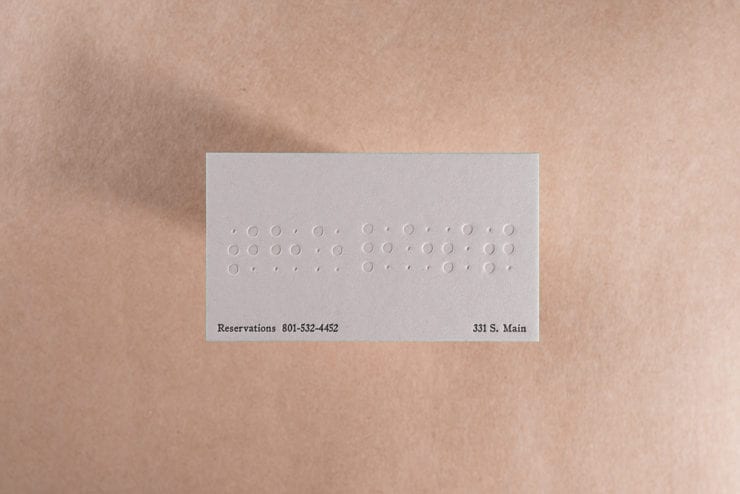

Card for Paymasters Inc. with blind letterpress pattern.

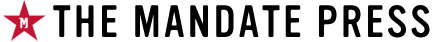

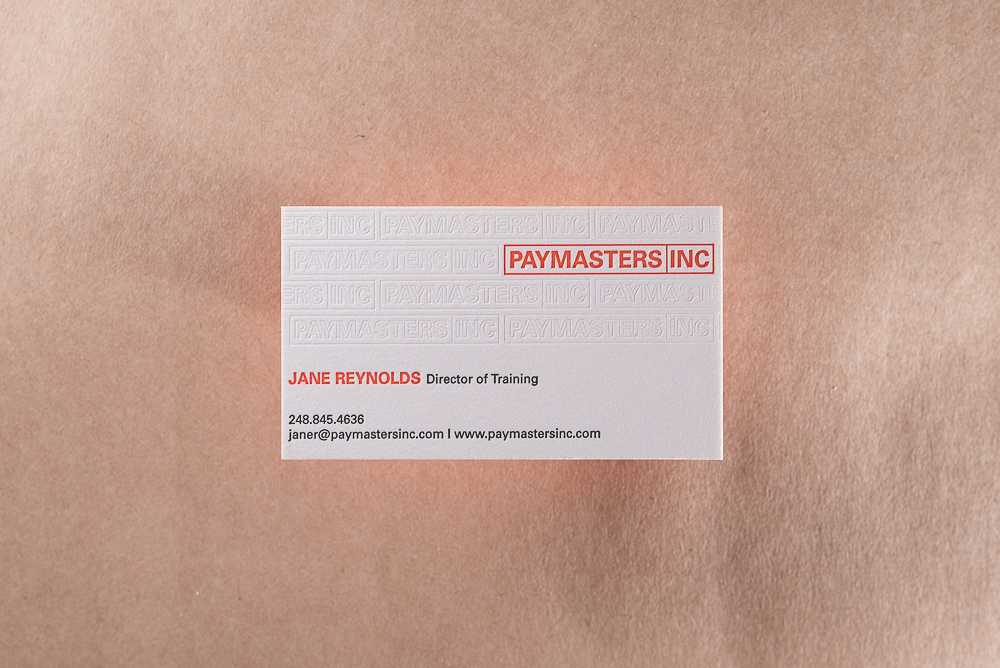

Cards with blind letterpress braille pattern for The Rest.

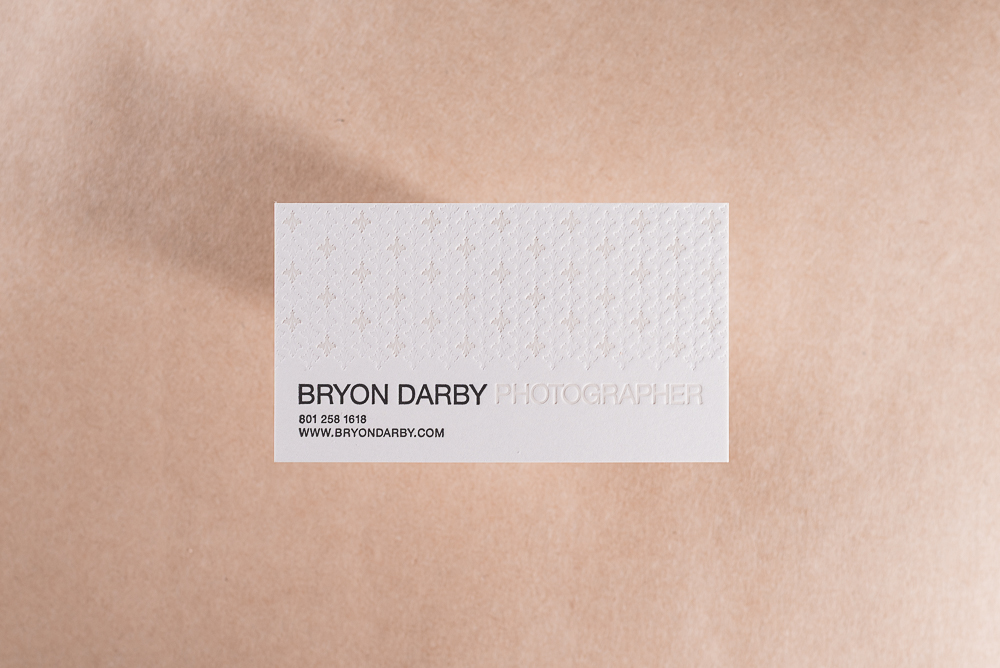

Business card with blind letterpress pattern for Bryon Darby.

Blind letterpress impression on black paper for Jacquie Aiche.

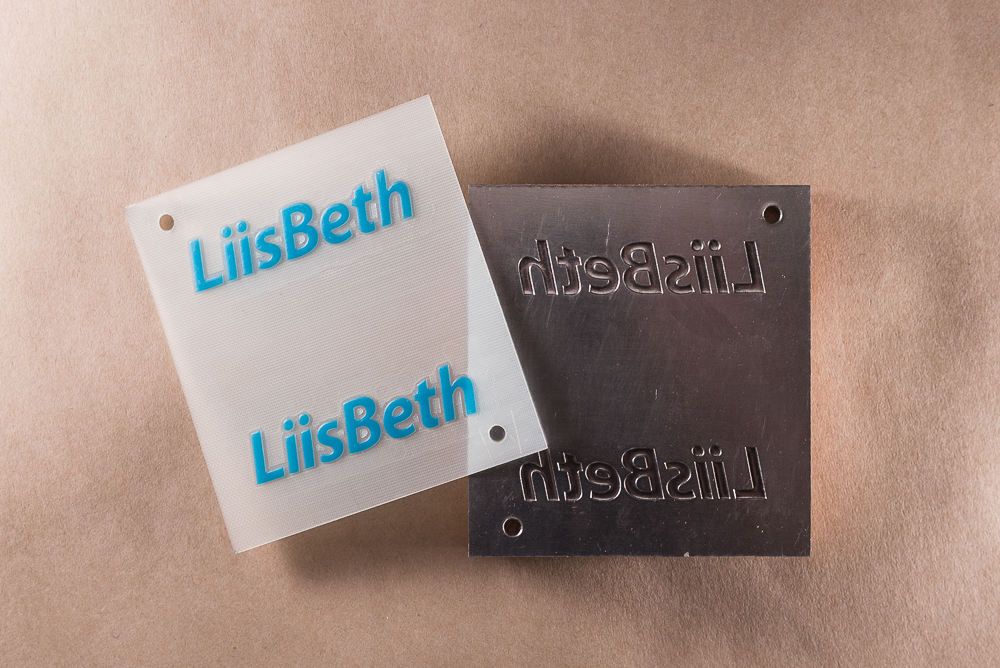

Emboss/Deboss die for LiisBeth.

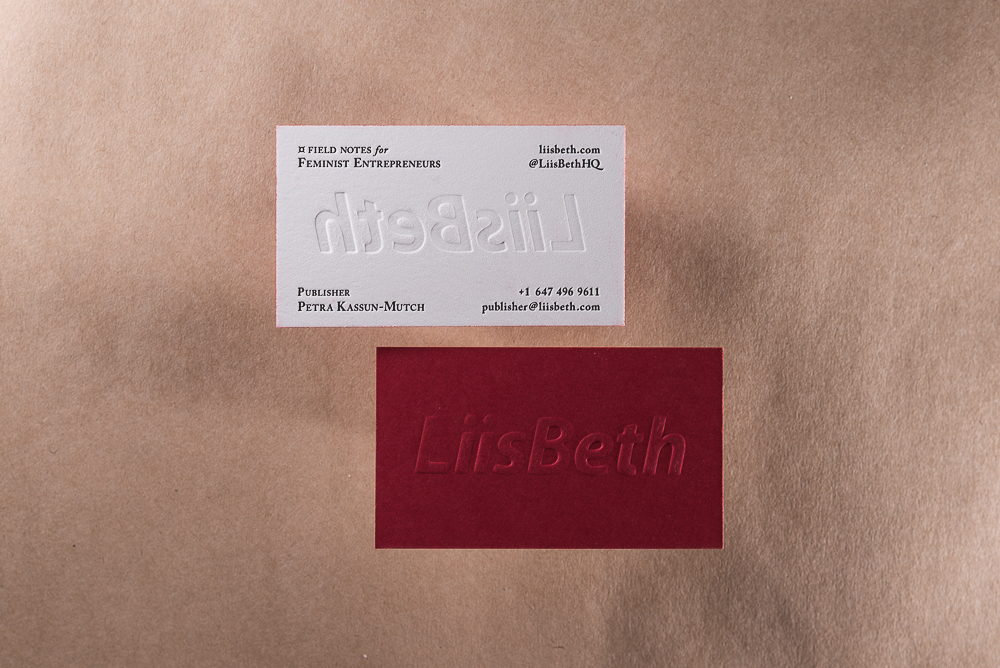

Front (top) and Back (bottom) of Emboss/Deboss business card for LiisBeth.

Emboss/Deboss business card for White Label Partners.

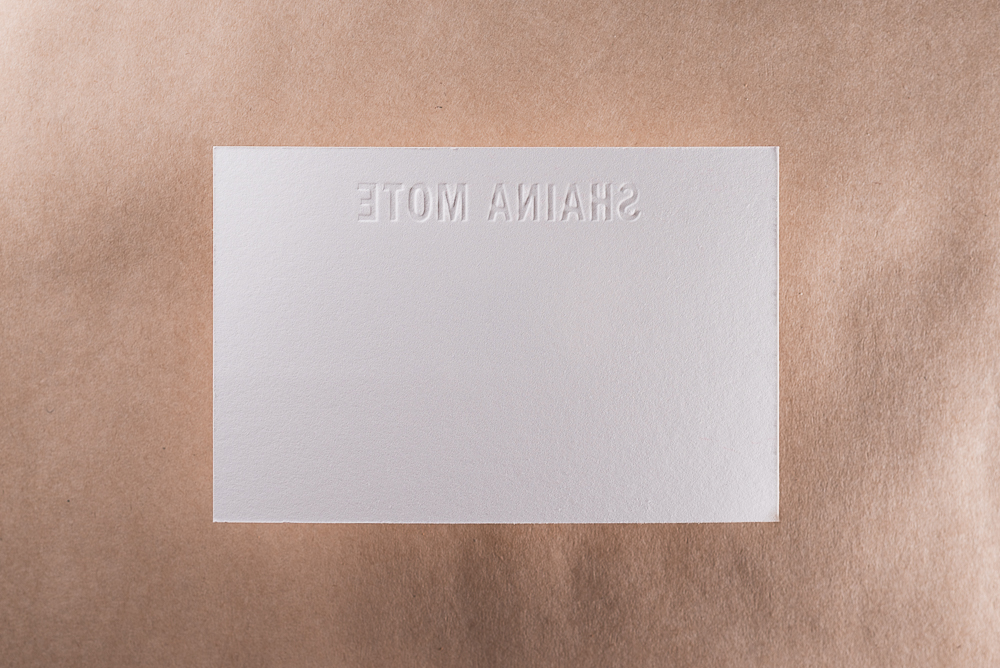

This is the deboss side of the Shaina Mote notecard.

This is the emboss side of the Shaina Mote notecard.

Cheers,

/Matt